JCTIMES owns world-advanced R&D technology for extrution die

production.We've accumulated production data of more than 35,000

dies,ensuring to supply dies with stable quality and innovation.There

are more than 300 sets of 2100mm PC hollow profile dies and 200 sets of

PP hollow profile dies with different specifications serving at our

global customers' factories.

Self-developed multi-layer co-extrusion hollow profile die series

including structures of multi-layer honeycomb,'Click' type structure,PC

trapezoid structure,etc. It's mainly used for industry

packaging,advertisement material,stationery product,building material

and so on.

Extruded hollow board has remarkable characteristics such

as anti-fire,heat insulation,UV protection,shock resisting and high

transparency.

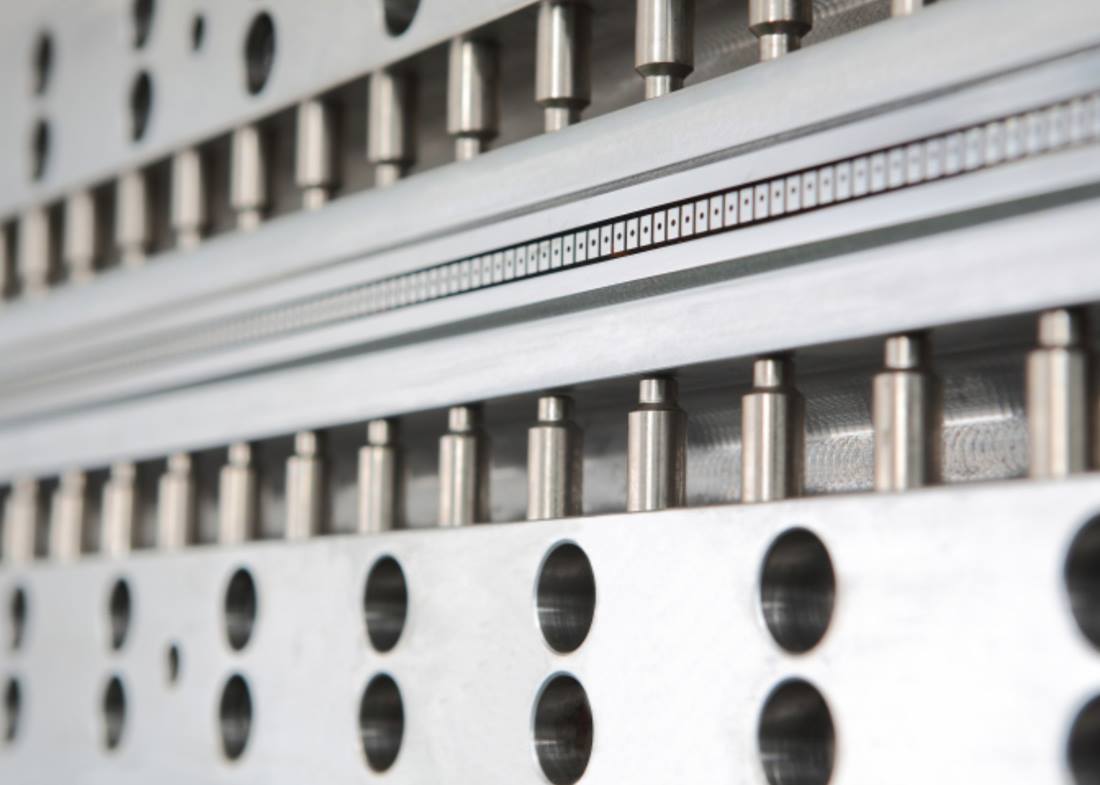

· Adopting unique structure of interchangable male for different shape

· Optimized flow channel designed by professional simulation software,ensuring uniform and stable melt flow.

·

Independent airflow control units provide stable and balanced airflow

in short time thus saves the cost.

· Die cavity roughness is finished at 0.02-0.03μm。

· Die lip roughness is finished at 0.01-0.02μm。

· Die lip's sharp angle at R0.03mm。

· For the male, the tooth's roughness is finished at 0.04-0.05μm。

· For PC hollow sheet die,product thickness ranges from 4mm to 40mm, the standard width is 2100mm.

· For multilayer structure hollow sheet die,product thickness can reach 80mm.

· For PC trapezoid structure hollow profile die, the wave height can be made as high as 100mm.

· PP hollow sheet die, product thickness ranges from 2-12mm , width 1200-3000mm.

Type of Product Structure

Main type:Twin wall,honey comb,X type.

· PC hollow corrugated sheet thickness: 4-20mm, wave height: 20-60mm,or customized

· PP hollow corrugated sheet thickness: 2-12mm, wave height: 20-60mm,or customized

· With restrictor bar, suitable for all kinds of PP raw materials .

· Fine adjustment system is easily operated.

· Integral type die body: avoid any leakage of the material,easy to maintain and clean, prolong the life time.

·

Vacuum shaping mould: with special texture on the surface and hardening

treatment,independent vacuum zone control system with vacuum edge

sealing device.

· 'Click' type structure design: without using

stainless supporting frame or aluminum accessories,attaining better

sealing performance and shortening the installation time.

·

UV+PC+UV,UV+PC co-extruded hollow sheet, made by our hollow sheet die

and multi-layer feed block,saving the cost of UV up to 30%.

Multilayer Co-extrusion Technology

· Feed block feature: modular structure,co-extrusion way such as A/B/C/B/A,A/B/A or A/B,advantages as below:

More stable, more uniform in product thickness

Easy cleaning

Flow channel is designed in herring bone structure,making melt flow go more fluently

Other Products

Other Products