With our advanced flow channel analyzing software and more than 10

years' design and production experience,we can supply our customers the

most suitable feed block with the strongest practicality. In

particular,the inlet and outlet dimension of feed block can be

customized to connect directly with extruder and die,without requesting

for transition part thus save the cost.

· Suitable for processing multilayer and multicolor coextrusion of polymers with similar flow rate and processing temperature.

·

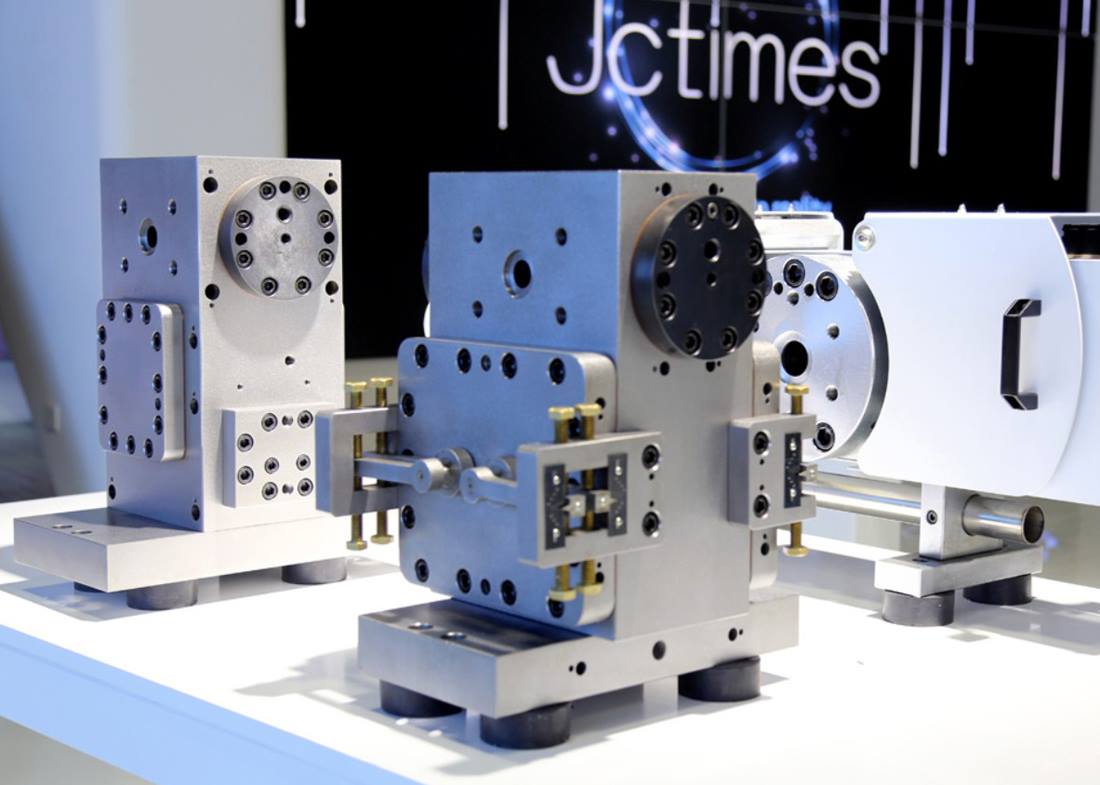

Conventional feed block structures including: insert type,mandril

type,vane type. Besides,dedicated feed block for gradient film and

hollow sheet.

· Accurate flow channel design assures perfect processing precision.

· Percentage of each layer can be adjusted on line in larger range.

·

To get co-extrusion of different layers,only by easily changing the

split-flow bars,without dismantling the whole set of feed block.

· The surface flow channel is designed into a streamline through a pack

of inserts,to achieve the best uniformity of coextrusion.

· When the

polymer fluidity of surface layer or proportional change of output

varies a lot, only need to replace a set of inserts,without modification

or change a new feed block.

· When there is need for changing the

layer composition structure,only by installing inserts with flow channel

or normal block. The inner structure of feed block is simple and there

is no dead ends in flow channel.

Feed block for PVB gradient film

· Special patented structure design,producing gradient film,the most

common application is PVB film for automotive glass interlayer.

·

By changing insert,the core part,color stripe can be adjusted to appear

in the middle,at the both sides or at one side of the film.

Other Products

Other Products