The meltblown nonwoven process is using high-speed hot air to draw the

melt stream from spinneret hole of die. After this process,microfiber

will be formed and gathered on the collecting screen or roller.At last

the meltblown nonwoven fabric is formed by the self-bonding microfiber.

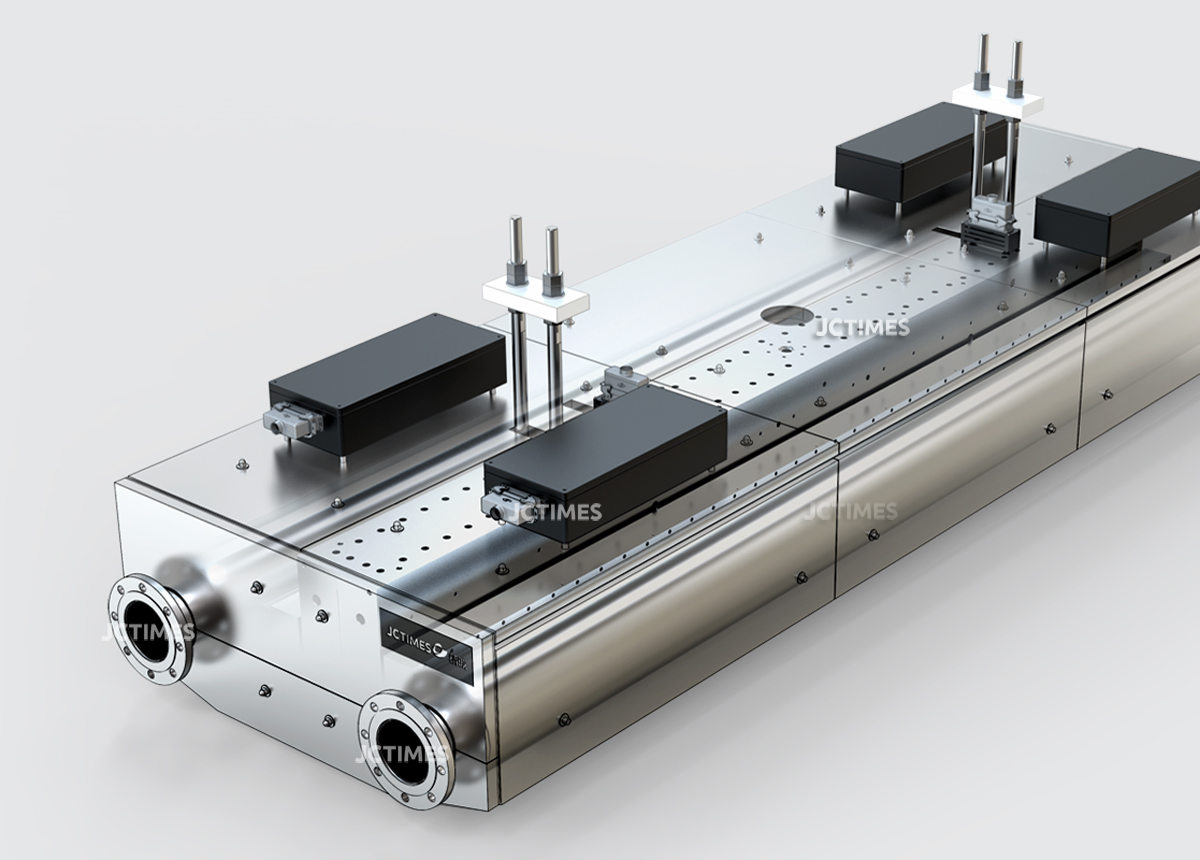

The die acts a very important role in this process,especially for

fabric's thickness uniformity.So it requires high-precision

manufacturing for die.

· The most optimized coat-hanger flow channel will be design,according

to polymers'different characteristics,including viscosity,processing

temperature and flow velocity,thus make melt distribution more uniform.

· Roughness of mold cavity is at 0.01um-0.03um

· The special heating device is with high efficiency of heating and heat exchanging, while with low energy consumption.

· Special air chute structure makes air pressure stable and air flow of both sides symmetrical.

· Width of air gap can be adjusted easily and real-timely.

· Standard type:1000mm ,1600mm, 3200mm.Customization is available.

· Spinneret hole diameter: 0.2mm-0.4mm. Spinneret hole center distance: 0.7mm-1.5mm.

· Processing temperature: Below 350℃. For carbon fiber,330℃—350℃. For PP and PET,below 300℃.

· Die steel: SUS630/SUS420/2316/1.2714

Thermal insulation material, filter material, oil absorption material,

medical and health material, environmental protection material, clothing

material, lead acid battery separator material, industrial and

household cleaning material,etc.

Processing polymers:

PET/PBT/PA/PP/PE/PTFE/PS/EMA/EVA/TPU/Carbon fiber,etc.

Other Products

Other Products